Projects

Soaring above the clouds or exploring the deep blue?

Our super lightweight construction techniques excel under extreme pressure. Your product will benefit from synergies and knowledge transfer gained in our other industry sectors.

Keep pushing the boundaries with our practical and reliable solutions.

Superyacht

Building special equipment for the superyacht industry is one of our strengths. From masts, biminis, and fireboxes to swimming pools, gangways, and more. All designed, engineered, and built in-house.

Maritime

Total precision with innovative solutions.

Our composite structures can integrate pre-manufactured fittings. Effective fire protection, laser technology and 3D tracking systems deliver perfect alignment and orientation.

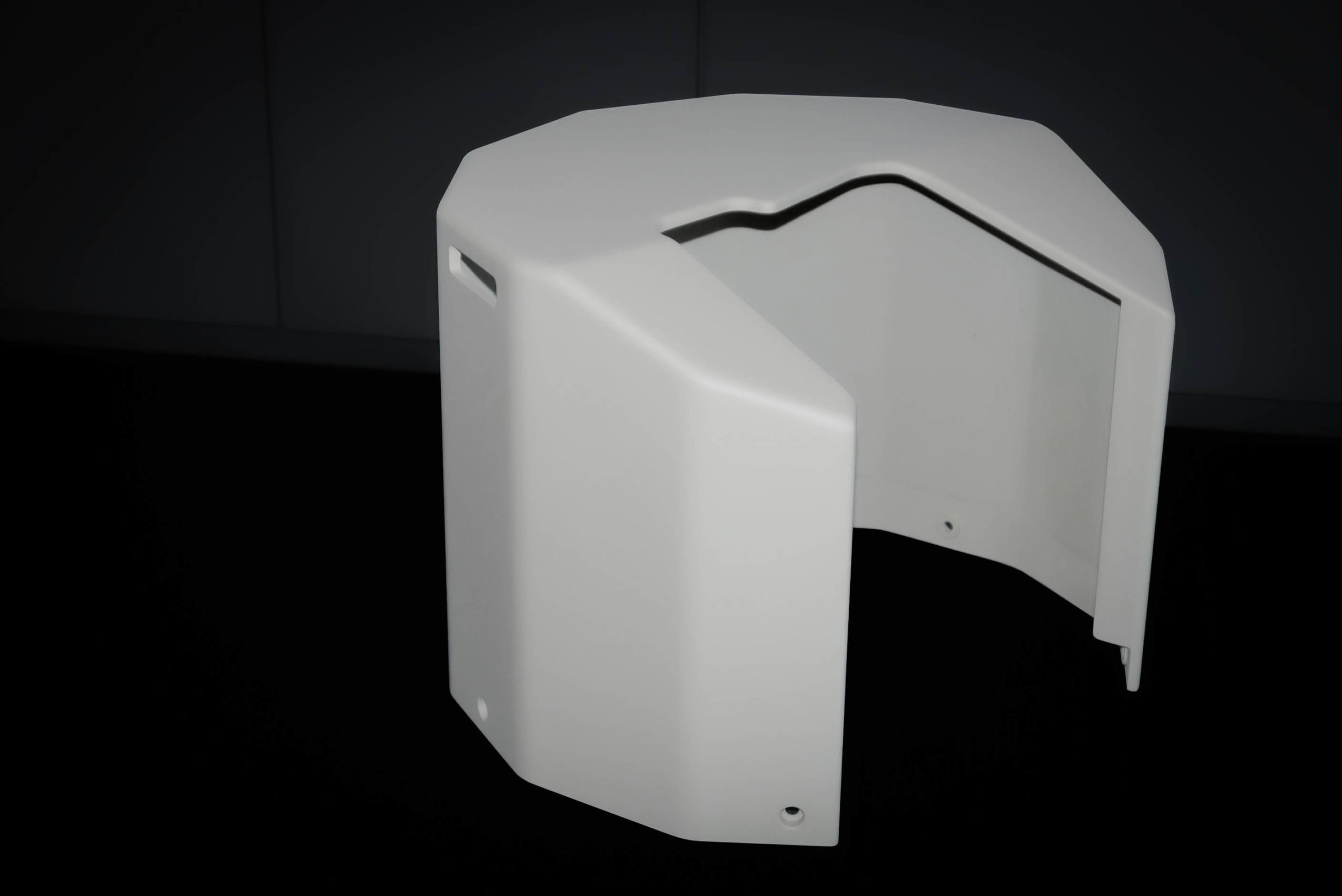

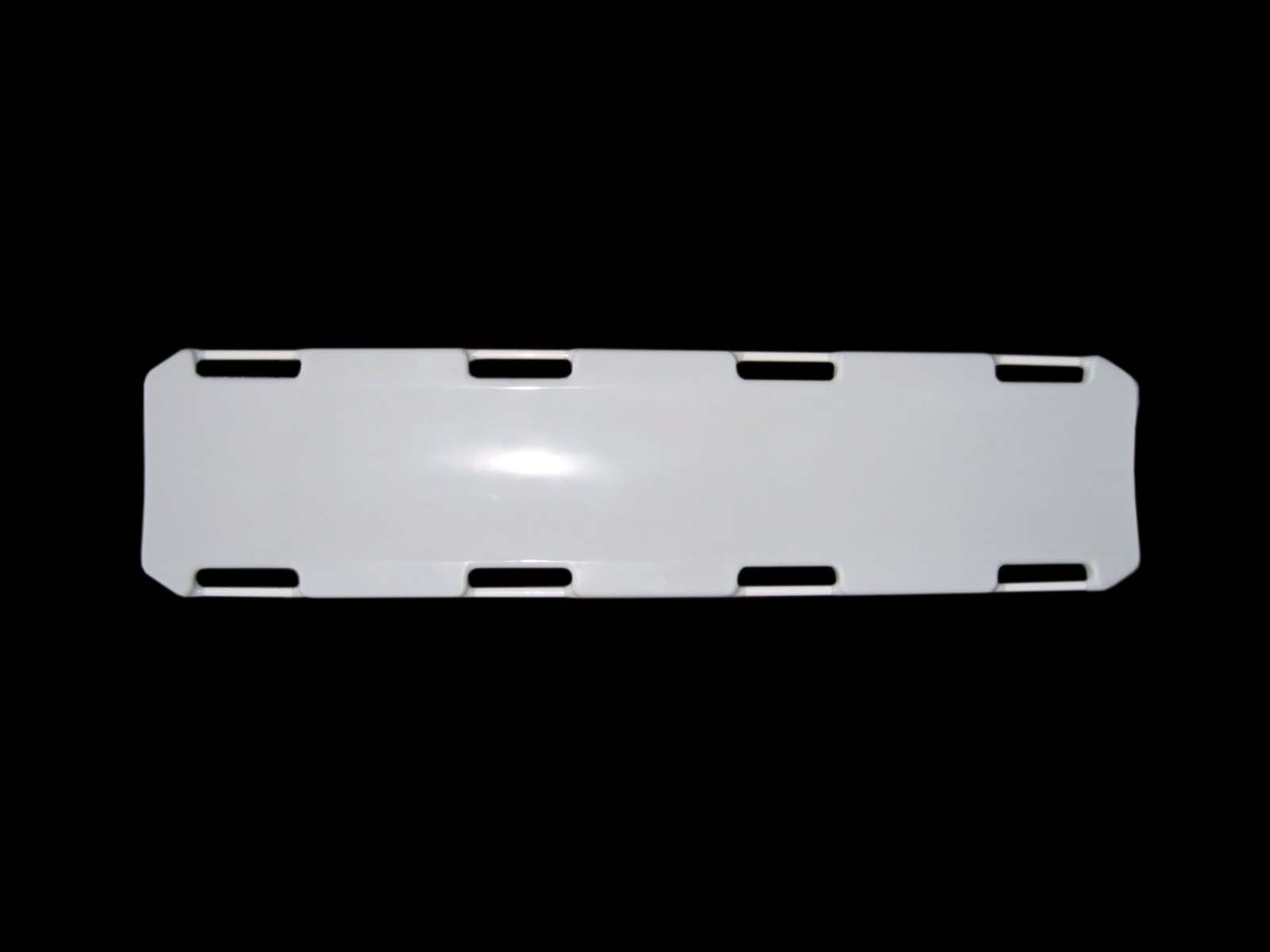

Military

Composite fibre materials are ideally suited to use as ballistic armouring or for the protection of operators of fast-rotating machinery.

- load-bearing and energy-absorbing materials

- very light protective shields

- freedom in the geometrical design

- saving around 60% over comparable steel armouring.

Aerospace

Maximum dimensional stability thanks to our carbon resistance heating technology integrated into the mould:

- no heat distortion, no warping

- ultra-light weight carbon fibre reinforced sandwich construction

- super-fast cycle times as a result of heating precise areas of material.

Our solution uses 90% less energy than external heating.

Renewable energy

Large-scale, complex parts benefit from our technology to save weight and meet exacting requirements for precision.

Architecture

Working on hand with architects and artist to develop special projects, like Jacob’s crown, located in Bremen’s city centre.

mEDICAL

From development to production process optimisation, our comprehensive portfolio of services gives you the edge for implementing new fibre composite technology.

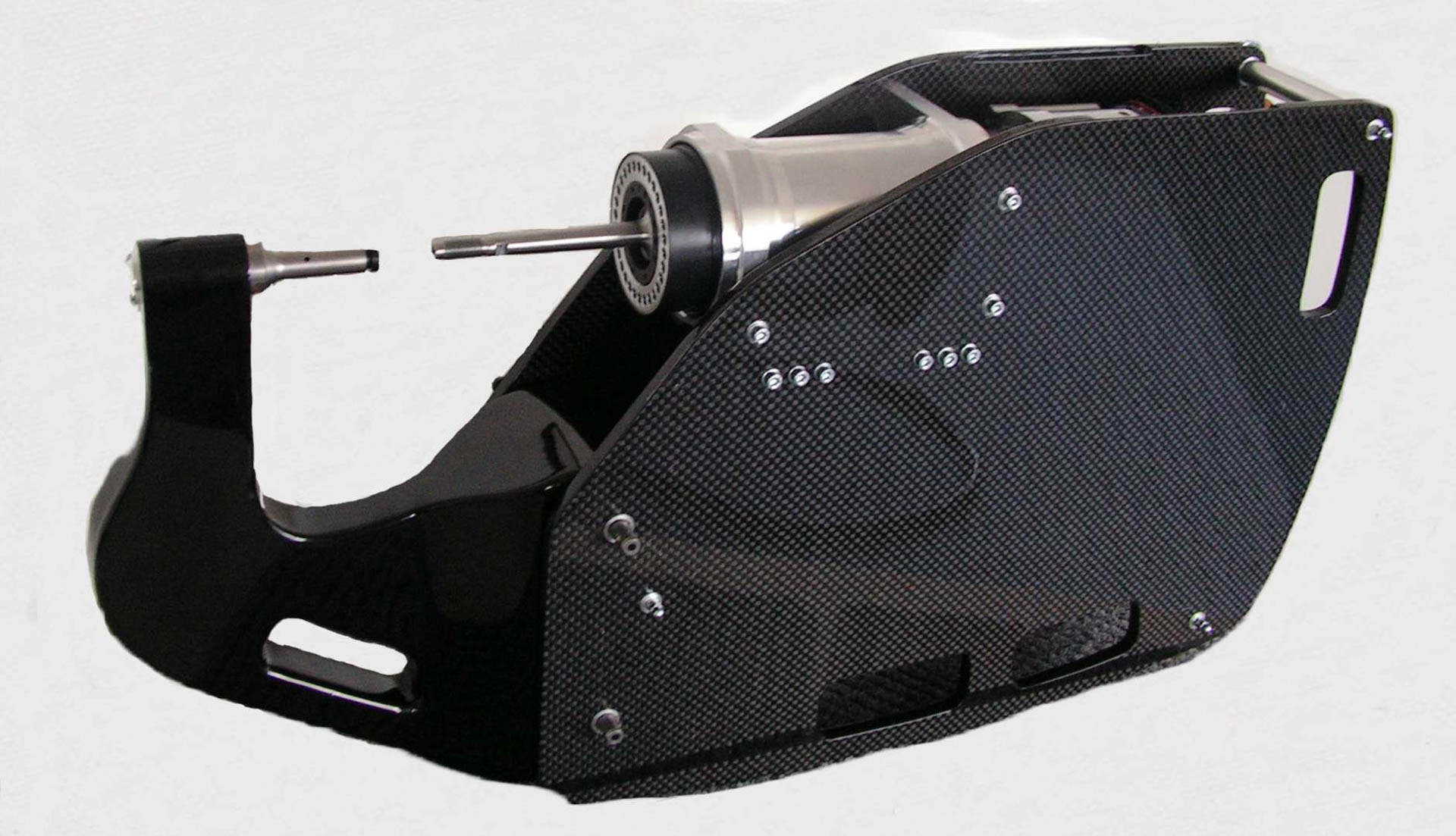

Automotive

When the requirenment is lightweight, we find the solution.

Like the structure for these friction point welding tongs in sheet metal forming. Made in carbon fibre web sandwich, using a roving winding technique.